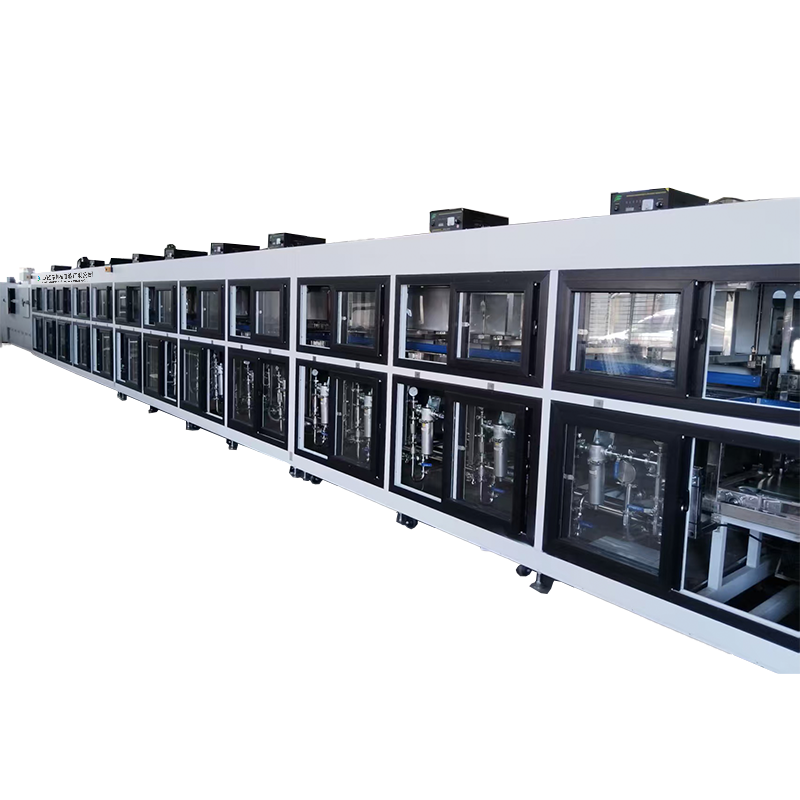

Upper and lower chamber hardening oven

1、Definition and function

Upper and lower chamber oven is an industrial or laboratory heat treatment equipment that divides the heating area into an upper chamber and a lower chamber. The two chambers can be controlled by independent or linkage temperature to achieve phased heating, partition treatment or simultaneous different processes, which is suitable for scenes requiring hierarchical temperature control or process differentiation, such as material pre-drying, curing, cooling, etc.

2、Structure and design characteristics

Cavity layout:

Upper and lower layers: The upper chamber is usually used for high temperature treatment (such as curing), the lower chamber is used for low temperature drying or cooling, and the middle is separated by insulation.

Independent/linkage control: Support independent temperature control (the temperature difference between the upper and lower cavities can reach more than 100 ° C) or linkage program (the temperature of the upper and lower cavities changes synchronously according to the set curve).

Heating and ventilation system:

Independent heating module: The upper and lower cavities are equipped with heating tubes (such as stainless steel or quartz tubes) to ensure independent temperature control.

Forced convection circulation: built-in multiple fans to ensure the uniformity of temperature in each chamber (temperature difference ≤±1.5℃).

Intelligent control system:

Dual channel temperature control: upper and lower chamber independent PID regulation, support programmatic heating, heat preservation, cooling.

Touch screen operation: centralized display of upper and lower chamber temperature, time, running status, support data export.

Safety design:

Chamber door linkage power off protection, over temperature alarm, leakage protection.

Ceramic fiber or rockwool insulation reduces heat loss and the risk of external burns.

3、Technical parameters

Parameter Typical values/Description

Total volume 100L-2000L (upper cavity ratio can be customized)

Temperature range Upper chamber: 50℃ -300 ℃; Lower chamber: room temperature -200 ℃

Temperature control accuracy ±1℃ (single cavity)

Power supply 380V/50Hz (three-phase)

Material outer box: cold rolled steel spray; Inner chamber: SUS304 stainless steel

4、Application scenarios

Electronic Manufacturing:

PCB board production: high temperature curing solder resistance ink in the upper chamber, low temperature drying circuit board in the lower chamber.

Composite material processing:

Prepreg treatment: the upper chamber solidifies the resin at high temperature, and the lower chamber gradually cools to prevent deformation.

Food processing:

Layered drying: the upper part is dehydrated at high temperature, and the lower part is kept at low temperature to maintain nutrients (to meet food grade material standards).

Laboratory studies:

Stage experiment: the upper chamber sintered material at high temperature, the lower chamber real-time cooling test performance.

5、Product advantages

1、advanced equipment technology, exquisite workmanship

2、Long normal service life, high pass rate, to the technical level of imported equipment, more cost-effective.

3、our company has nearly 20 years of experience in technical and after-sales service team, from design and production to after-sales service to provide customers with professional solutions.

6、Upper and lower chamber oven vs. independent multi-chamber oven

Contrast item upper and lower chamber oven independent four chamber oven

The structure design is layered up and down, suitable for multi-cavity independent stage process, suitable for multi-task parallel processing

Temperature control flexibility Large temperature difference between upper and lower cavities, suitable for step heating each chamber temperature independent, suitable for diverse needs

Lower cost (relatively simple structure) higher (more standalone systems)

Application scenario Phased process (such as curing + cooling) multi-variety, multi-parameter synchronous processing

7、Selection suggestions

Process requirements:

If you need to heat in stages (such as high temperature before low temperature), choose the upper and lower chamber oven.

For multi-task independent processing (such as simultaneous drying of different materials), choose an independent multi-chamber oven.

Space limitation:

Upper and lower chamber ovens have a small footprint and are suitable for workshops or laboratories with limited space.

Budget control:

Upper and lower chamber ovens typically cost less than stand-alone multi-chamber units.

8、Maintenance and precautions

Daily maintenance:

Clean the chamber residue regularly and check the heating tube and fan status.

Calibrate the upper and lower chamber temperature sensors to ensure temperature control accuracy.

Safe operation:

Avoid overloading or excessive stacking, which affects hot air circulation.

Do not open the chamber door frequently during high temperature operation.

Technical indicators

For more models of products, please contact us. We will be happy to serve you!

在線留言