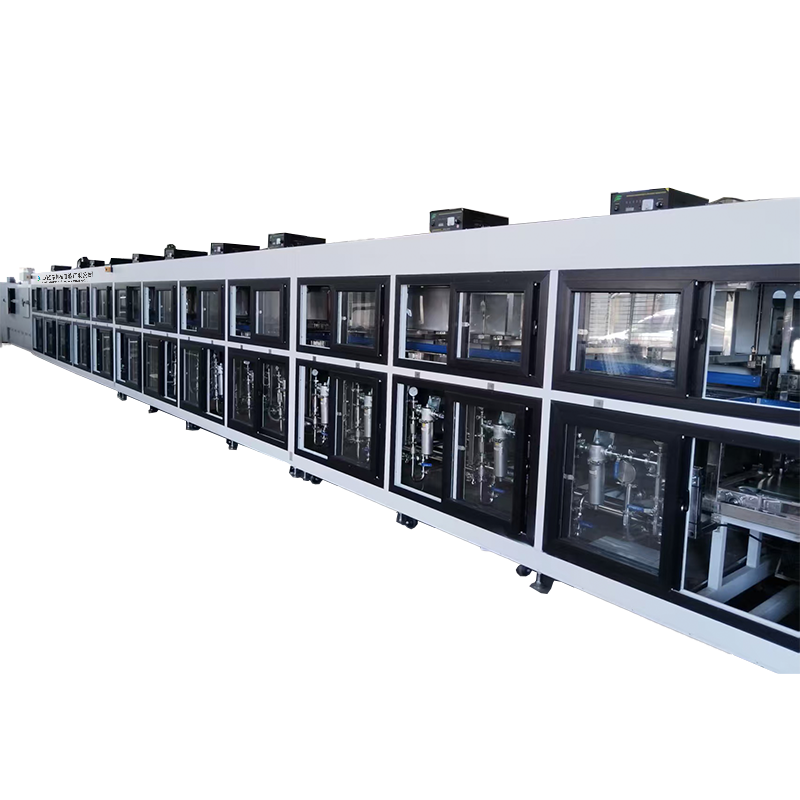

Water-cooled Chiller

Product information

It adopts an internationally-known brand full-closed scroll compressor,and the evaporator copper tube adopts internal and external screw-type reinforcing tubes.The surface of the copper pipe is threaded,the outer surface of the copper pipe is smooth,the cooling effect is good,no condensation occurs,and the loss of the cooling capacity is smal The condenser is processed into a trapezoidal low-ribbed tube,which enhances the heat transfer capacity.The surface of the copper tube is smooth,so that the water pressure is reduced,andit is easy to clean and maintain.Protection system devices include:compressor delay start protector,overload protector,high and low voltage protector,temperature control switch,etc.to ensure the normal operation of the unit.

1、 Definition and working principle of water-cooled Chiler

A water-cooled chiller is a type of refrigeration machine that dissipates heat through a water-cooled condenser, using a refrigerant circulation system (compressor, evaporator, condenser, expansion valve) to transfer heat to the cooling water, thereby providing low temperature chilled water for industrial or commercial systems. Its core advantages are high energy efficiency and stable operation, which is suitable for high-load and continuous operation scenarios.

2、Core components and workflow

Compressor:

Type: Screw type, centrifugal type, scroll type (select according to cooling demand).

Function: Compress refrigerant (such as R134a, R410a) to drive the refrigeration cycle.

Evaporator:

Shell and tube heat exchanger or plate heat exchanger, the refrigerant absorbs the heat of frozen water and evaporates.

Condenser:

Water-cooled design, through cooling water (such as cooling tower circulating water) to take away the refrigerant heat.

Expansion valve:

Adjust refrigerant flow and control evaporator inlet pressure.

Water pump and cooling tower:

Drive the cooling water circulation, through the cooling tower to dissipate heat to the atmosphere.

Working process:

The refrigerant absorbs the heat of the frozen water in the evaporator and converts it into a low-temperature gas.

Compressors compress low temperature gas into high temperature and high pressure gas.

The high-temperature gas is dissipated by cooling water in the condenser and condensed into a high-pressure liquid.

After the expansion valve depresses, the refrigerant re-enters the evaporator circulation.

3、Key performance parameters

Parameter: Typical values/Description

Cooling capacity: 10RT-1000RT (1RT≈3.517kW)

Chilled water temperature range :

Standard type: 5℃ -15 ℃; Low temperature type: -40℃ -5 ℃

Cooling water flow: according to the cooling demand, generally 3-5m3/h per RT

Energy efficiency ratio (COP): 4.0-6.0 (higher than air-cooled)

Power supply: 380V/50Hz (three-phase)

Noise : 75dB-90dB (soundproof enclosure required)

4、 Water-cooled vs. Air-cooled water cooler comparison

Comparison item | Water-cooled Chiller | Air-cooled Chiller |

Heat-dissipating method | Cooling by cooling water circulation (cooling tower) | Cooling by blower (no cooling tower required) |

High energy efficiency ratio (COP) | high(4.0-6.0) | low(2.8-4.5) |

Installation cost | High (cooling tower and water pipe system required) | Low (simple structure) |

Applicable scene | High load, continuous operation (e.g. factory, data center) | Small/medium load, mobile or outdoor scenes |

Maintenance requirement | Clean the condenser and water pipe regularly | Clean the fan and fins |

5、 Application Scenarios

Industrial Manufacturing:

Injection molding machine, laser cutting machine, chemical reactor cooling.

Commercial Buildings:

Chilled water supply for central air conditioning system.

Data Center:

The server cabinet dissipates heat and maintains a constant temperature.

Food and Medicine:

Low temperature storage, fermenter temperature control (need to meet health standards).

Product advantages

1、advanced equipment technology, exquisite workmanship

2、Long normal service life, high pass rate, to the technical level of imported equipment, more cost-effective.

3、our company has nearly 20 years of experience in technical and after-sales service team, from design and production to after-sales service to provide customers with professional solutions.

6、 Selection suggestions

Cooling capacity calculation:

According to the equipment heat (Q= power x efficiency) and ambient temperature, choose a redundancy of 20%-30% models.

Cooling water system matching:

The cooling tower capacity should match the cooling demand of the chillers (cooling water flow ≥ the rating of the chillers).

Function extension:

Frequency conversion control: Continuous operation scenarios with high energy saving requirements.

Explosion-proof design: chemical industry, oil and gas industry.

7、 Maintenance and maintenance points

Daily maintenance:

Check the water quality (pH value, hardness) of the cooling water every month to prevent scale from blocking the condenser.

Clean condenser lines (chemical cleaning or mechanical scrubbing).

Quarterly maintenance:

Check the refrigerant pressure and lubricating oil status, and replace or replace the refrigerant in time.

Calibrate temperature sensors and pressure switches.

Annual maintenance:

Comprehensive inspection of compressor, pump and valve tightness.

8、 Summary

Water-cooled chillers are the first choice for industrial and commercial refrigeration due to their high energy efficiency and large cooling capacity. When selecting the model, it is necessary to consider the cooling demand, cooling water system supporting and long-term operation and maintenance cost. Proper maintenance can significantly extend equipment life and reduce energy consumption. If you need to know more about the specific model or technical details, you can provide application scenarios and budget ranges for accurate recommendation!

Technical indicators

For more models of products, please contact us. We will be happy to serve you!

在線留言