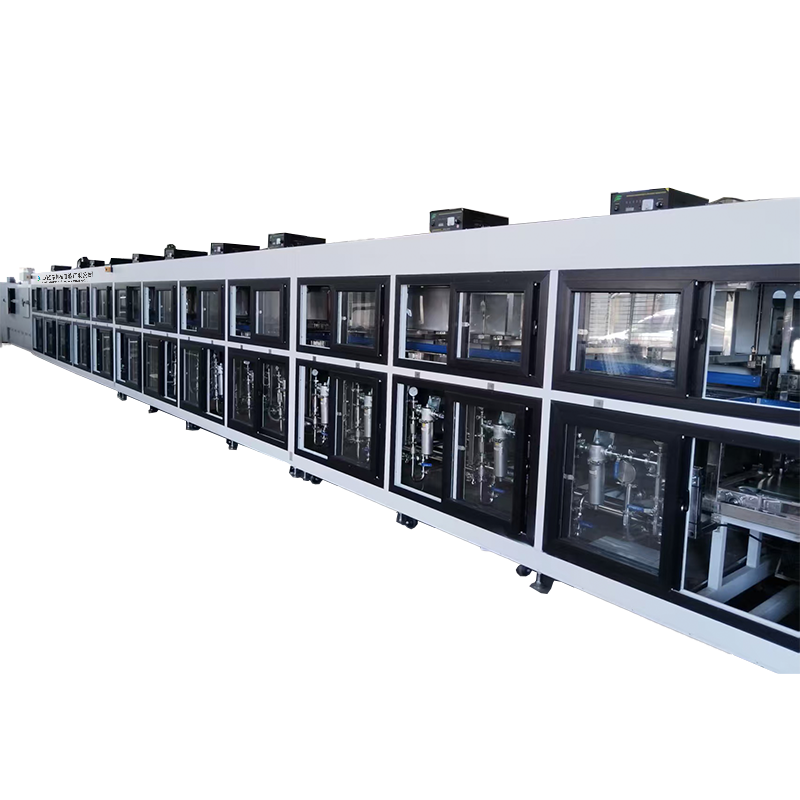

Polishing liquid mixing tank

Product introduction

1、 Definition and function of polishing liquid mixing tank

Buffing tank is a special equipment for mixing, storing and dispersing buffing liquid (CMP Slurry, metal slurry, etc.), which is widely used in semiconductor, optical, metal processing and other industries. Its core functions include:

Uniform mixing: Prevent abrasive particles in the polishing liquid (such as SIO2, Al?O ?) from settling or agitating.

Temperature control: maintain the constant temperature of the polishing liquid to avoid temperature fluctuations affecting the polishing effect.

Anti-contamination: Ensure that the polishing liquid is stored in a clean environment to prevent the introduction of foreign matter.

2、Equipment structure and working principle

1. Core components

Barrel Body:

Material: 316L stainless steel (corrosion resistance), PP/PTFE (anti-static, acid and alkali resistance).

Mixing system:

Mixer type: paddle type, anchor type, screw type (selected according to viscosity).

Drive motor: variable frequency speed regulation (0-500 rpm), power 0.5-15 kW.

Temperature control system:

Heating/cooling jacket: through the heat transfer oil or cooling water, temperature control range of 5℃-80℃.

Temperature sensor: PT100 probe, accuracy ±0.5℃.

Auxiliary system:

Liquid level monitoring: ultrasonic or float type liquid level gauge.

Cyclic filtration: on-line filter (0.1-1μm accuracy) to prevent agglomeration of particles.

2. How it works

The motor drives the agitator to rotate, forming laminar flow or turbulence, so that the abrasive and additives in the polishing liquid are evenly dispersed. The temperature control system regulates the liquid temperature through a jacketed medium to ensure chemical stability.

3、Technical parameters

Parameter Typical values/Description

Capacity 50L-5000L (customizable)

Mixing speed 0-500 rpm (stepless speed regulation)

Power 0.5kW (small) -15kW (large)

Temperature control range 5℃ -80 ℃ (accuracy ±1℃)

Contact material 316L stainless steel, PP, PTFE, fluorine rubber seal ring

4、 Application scenarios

Semiconductor Manufacturing:

Mixing and storage of CMP polishing fluid (chemical-mechanical polishing) without metal ion contamination.

Optical lens processing:

Constant temperature stirring of glass polishing liquid prevents particle settlement.

Metal surface treatment:

Circulating mixing of electroplating solution and pickling solution to improve process consistency.

Lithium battery materials:

Dispersion of positive/negative slurry ensures uniform coating.

Product advantages

1、advanced equipment technology, exquisite workmanship

2、Long normal service life, high pass rate, to the technical level of imported equipment, more cost-effective.

3、our company has nearly 20 years of experience in technical and after-sales service team, from design and production to after-sales service to provide customers with professional solutions.

5、 Selection and maintenance suggestions

1. Key points of selection

Polishing fluid characteristics:

High viscosity (such as lithium paste) : Choose anchor or spiral agitator.

Low viscosity (e.g. CMP polishes) : paddle or magnetic agitation.

Cleanliness requirements:

Semiconductor grade: 316L stainless steel + nitrogen seal + circulation filtration.

Industrial grade: PP material + mechanical seal.

Capacity matching:

Select capacity according to production line requirements (e.g. 500L/ batch).

2. Maintenance

Daily maintenance:

Clean the inner wall of the barrel weekly and check for seal wear.

Calibrate the temperature sensor monthly and clean the filter.

Long-term maintenance:

Replace the agitator bearing oil every year to test the motor insulation.

Complete inspection of the clamp pipe every 2 years to prevent leakage.

6、Common problems and solutions

Problem cause analysis solution

The particle settling stirring speed is insufficient or the time is too short to increase the rotational speed and prolong the stirring time

Temperature fluctuation large jacket medium uneven flow check pump valve, adjust flow

Seal leakage seal ring aging or improper installation Replace the seal ring, recalibrate the shaft

Motor overheating load is too large or poor heat dissipation reduce the speed, clean the heat dissipation fan

7、 Technology development trend

Intelligent:

Integrated Internet of Things (IoT) to monitor viscosity and particle distribution in real time.

AI algorithm optimizes mixing parameters and ADAPTS to different recipes.

Greening:

Low energy motor design to reduce carbon footprint.

Biodegradable materials replace traditional seals.

For more models of products, please contact us. We will be happy to serve you!

在線留言