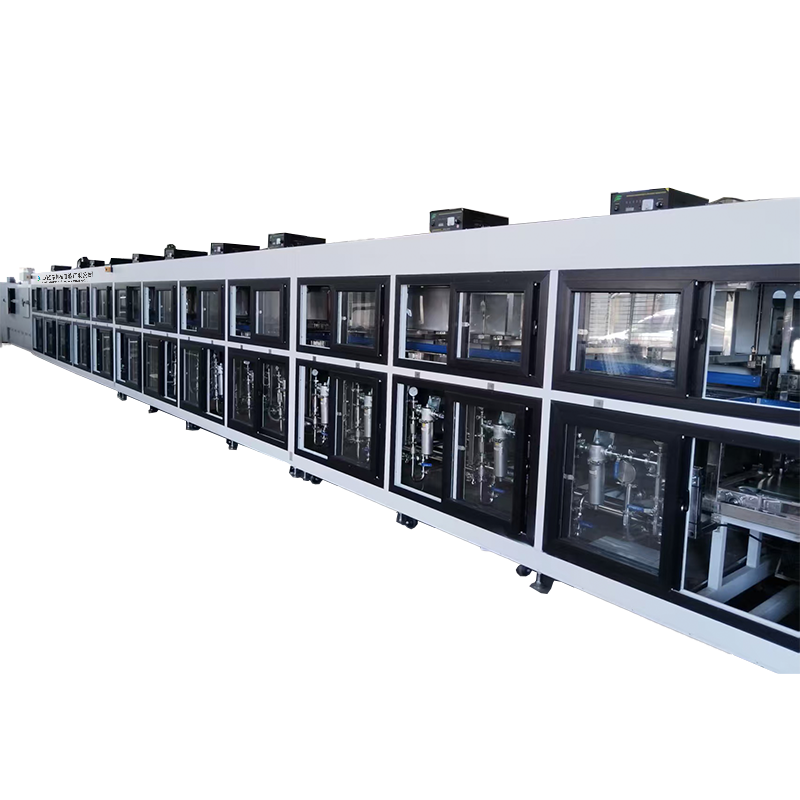

Dust-free Workbench before Coating(Simplified)

Product information

1、The top chamber adopts a double inlet fan and the outlet area is concentrated in the middle

2、The upper chamber uses a single-side fan circulation

3、The lower chamber circulation uses blades and adopts medium efficiency air filter .

4、Double fluorescent lamps are installed on the top of the worktable

5、When the lower chamber door is open, the motor stops automatically to prevent external dust from entering the chamber.

1、Function of dust-free workbench

The Clean Bench is a machine that provides a locally high cleanliness environment through an efficient filtration system. It is mainly used to clean, place and pretreat substrates before coating, ensuring that the substrate surface is free of dust, particles or organic contaminants, thereby improving coating quality and adhesion.

2、Core types and application scenarios

Vertical laminar flow clean table

Air flow direction: The air flows vertically from top to bottom and is purified by high efficiency filter (HEPA/ULPA) to form a clean area.

Application scenario: Suitable for fine cleaning of substrates before coating, pre-treatment of optical lenses or semiconductor wafers.

Horizontal laminar flow clean table

Airflow direction: Air flows horizontally, from one side of the operator to the other.

Application scenario: It is suitable for the pre-coating process where materials need to be frequently removed and placed (such as temporary storage after metal parts are cleaned).

Biosafe dust-free workbench

Features: Equipped with UV germicidal lamp and negative pressure system to prevent cross contamination.

Application scenario: Processing of biosensitive materials (such as coating substrates for medical devices) before coating.

Product advantages

1、advanced equipment technology, exquisite workmanship

2、Long normal service life, high pass rate, to the technical level of imported equipment, more cost-effective.

3、our company has nearly 20 years of experience in technical and after-sales service team, from design and production to after-sales service to provide customers with professional solutions.

3、Key technical parameters

Parameter Typical values/Description

Cleanliness level ISO 3 (Class 1) to ISO 5 (Class 100)

Filter type HEPA (filtration efficiency 99.99% @ 0.3μm) or ULPA (99.999% @ 0.12μm)

Wind speed control vertical laminar flow: 0.3-0.5m/s; Horizontal laminar flow: 0.4-0.6m/s

Working area size Single person type: 1200×600×600mm; Double type: 1800×600×600mm

Noise ≤65 dB(A)

4、Operation specifications before coating

Preparation for startup:

Start the fan and UV lamp 30 minutes in advance to ensure the stability of the clean area.

Use a particle counter to check the cleanliness of the work area (target ≤100 level).

Substrate treatment steps:

Pre-cleaning: Wipe the substrate surface with a dust-free cloth dipped in high purity isopropyl alcohol (IPA).

Placement: Base material in the center of the table, avoid near the edge (airflow disturbance area).

Electrostatic elimination: Use ion fan or electrostatic brush to eliminate static electricity on the surface of the substrate to prevent adsorption of particles.

Personnel operation requirements:

Wear dust-free clothing, gloves and masks to avoid human dander or respiratory contamination.

The operation is light and slow to reduce airflow disturbance.

5、Equipment selection suggestions

Select according to cleanliness requirements:

Optical coating: ISO Class 3 (Class 1) required, ULPA filter + vertical laminar flow recommended.

Industrial coating: ISO 5 (Class 100), optional HEPA filter + horizontal laminar flow.

Select by process compatibility:

For integrated ion fan or UV sterilization, choose a modular design table.

If the size of the substrate is large, the option is to widen and deepen the working area (such as 1800×800×800mm).

6、Maintenance

Daily maintenance:

Clean the table after daily use and wipe the residual solvent with a dust-free cloth.

Monthly monitoring of wind speed and pressure difference to ensure the uniformity of air flow.

Filter replacement:

HEPA filter: Replace every 1-2 years or when the pressure difference is ≥250Pa.

Pre-filter: Clean or replace every 3-6 months.

Calibration and Certification:

Every year, a third party testing organization is commissioned to conduct cleanliness certification (ISO 14644 standard).

7、Precautions

Prohibited operation: Activities that produce dust (such as grinding and cutting) in a dust-free workbench.

Emergency treatment: If accidental leakage of chemical reagents, immediately shut down the fan and thoroughly clean.

Technical indicators

For more models of products, please contact us. We will be happy to serve you!

在線留言