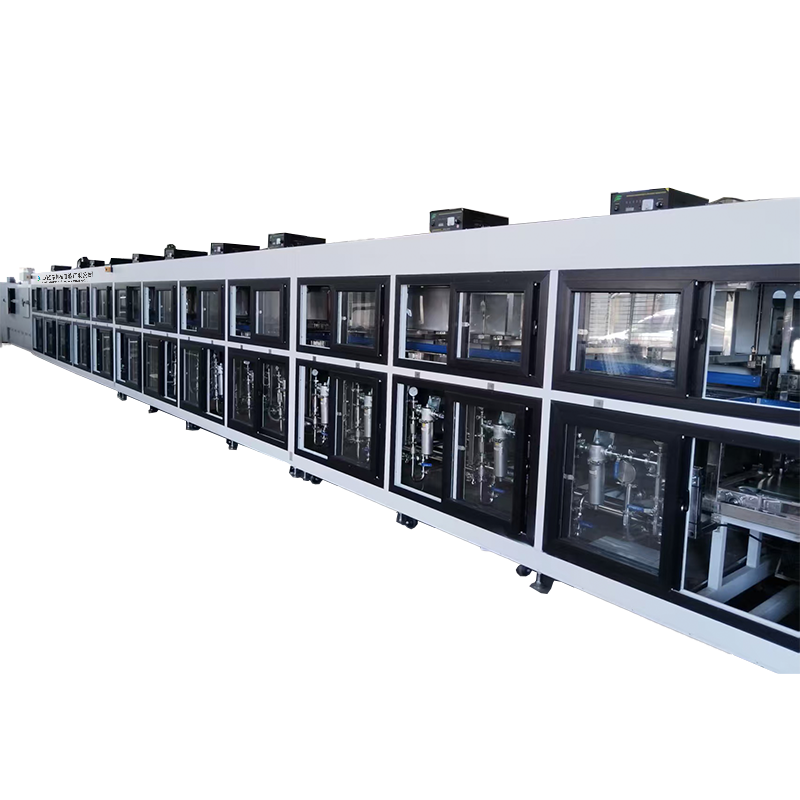

Conveyor System

Produce Structure Diagram

Product information

1、Definition and function of the Conveyor System

Conveyor System is a kind of equipment that continuously transports materials, workpieces or products through mechanical or automated devices, which is widely used in manufacturing, logistics, warehousing, food processing and other fields.

Its core functions include:

Improve efficiency: achieve continuous, automated transportation and reduce manual handling.

Precise control: Through the speed adjustment, positioning system, to ensure the synchronization of material transmission.

Flexible adaptation: Support a variety of material forms (bulk, box, pallet, etc.) and process requirements.

2、Classification and working principle of the conveyor system

1.Classified by drive type

Power transmission line:

Principle: The motor drives the belt, chain or drum.

Type: belt conveyor, chain conveyor, roller conveyor.

Features: Suitable for long distance, high load transportation, can be integrated automation control.

No power transmission line:

Principle: Rely on gravity or manpower to push the material to slide (such as slide rail, roller table).

Features: simple structure, low cost, suitable for short distance light load transport.

2. Classified by structure

Belt conveyor line:

Material: Rubber, PVC, PU, etc., anti-wear, anti-static.

Applications: Light industry (food, electronics), express sorting.

Drum conveyor line:

Type: Powered roller (electric drive) or unpowered roller (gravity roll).

Application: logistics warehousing, heavy machinery parts transportation.

Chain plate conveyor line:

Material: Metal (stainless steel, carbon steel), plastic chain plate.

Application: High temperature, high humidity environment (such as automobile painting line, cleaning line).

Screw transmission line:

Principle: The material is moved vertically or horizontally by rotating the spiral blade.

Application: Powder, granular materials (such as grain, chemical raw materials).

Suspension conveyor line:

Principle: The material is suspended in the air rail and transported by chain or electric hoist.

Application: automobile manufacturing, garment hanging system.

3、Core components and technical parameters

Parameter Typical values/Description

Conveying speed 0.1-5 m/s (belt/chain plate); 0.05-1 m/s (roller)

Load capacity belt: ≤50 kg/m2; Chain plate: ≤2000 kg/m

Conveying length single machine 1-100 m, can be multi-segment splicing

Power 0.5-50 kW (depending on load and speed)

Material Carbon steel, stainless steel, food grade plastic

4、Application scenarios

Manufacturing Industry:

Automobile assembly line (suspension conveyor), electronic product assembly (anti-static belt line).

Logistics Warehousing:

Express sorting (roller line), three-dimensional warehouse entry and exit (shuttle + transport line).

Food processing:

Packaging line (stainless steel chain plate line), sterilization cooling (mesh belt conveyor).

Pharmaceutical industry:

Material transfer in aseptic workshop (clean belt line).

Product advantages

1、advanced equipment technology, exquisite workmanship

2、Long normal service life, high pass rate, to the technical level of imported equipment, more cost-effective.

3、our company has nearly 20 years of experience in technical and after-sales service team, from design and production to after-sales service to provide customers with professional solutions.

5、Selection suggestions

Select by material characteristics:

Bulk/powder: spiral conveying line, pneumatic conveying system.

Box/tray: drum line or chain plate line.

Precision parts: belt wire (anti-static, low vibration).

Select according to environmental requirements:

High temperature/corrosive environment: stainless steel chain plate wire.

Clean workshop: food grade PU belt + fully enclosed structure.

Select by automation requirements:

Basic transport: no power drum line.

Intelligent sorting: Power drum line + barcode scanning/visual recognition system.

6、Maintenance and optimization

Daily maintenance:

Clean the surface of conveyor belt/roller regularly to prevent material residue.

Check the lubrication status of the motor and bearing, and replace the worn parts in time.

Energy saving optimization:

The frequency converter is used to adjust the speed and match the actual load demand.

Install energy consumption monitoring system to optimize operating efficiency.

7、Technological development trends

Intelligent:

Integrated AI visual sorting and RFID tracking to achieve unmanned operation.

Flexibility:

Modular design, quickly adjust the transmission line layout to adapt to production changes.

Green energy saving:

Low noise motor, lightweight materials to reduce energy consumption.

For more models of products, please contact us. We will be happy to serve you!

在線留言