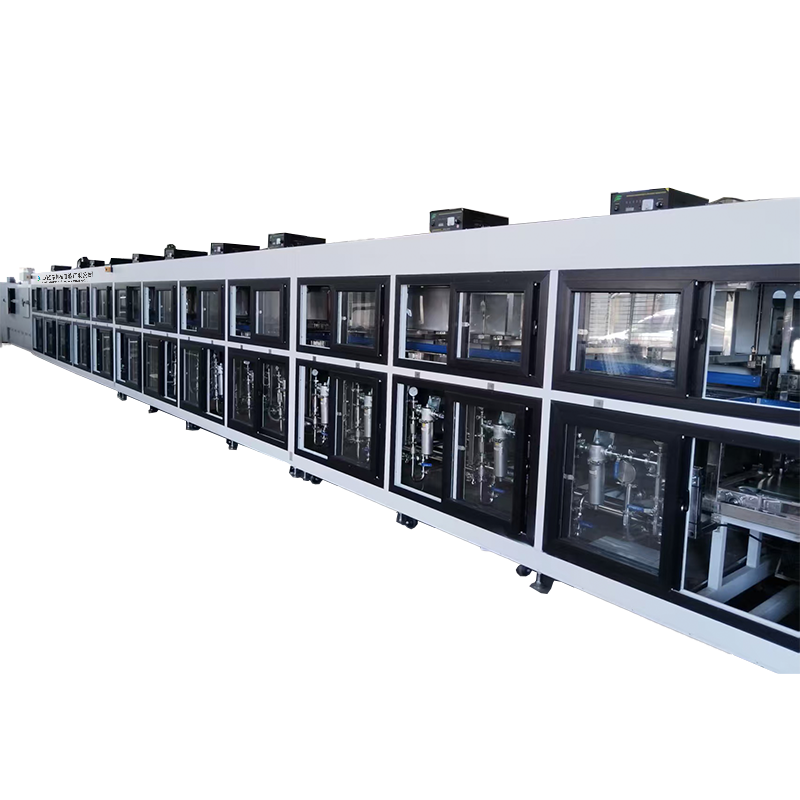

Ultra-pure water machine

Product introduction

1、Definition and standard of ultra-pure water machine

Ultrapure Water (UPW) Ultrapure water (UPW) ** refers to high-purity water with a resistivity ≥18.2 MΩ·cm (25 ° C), total organic carbon (TOC) ≤5 ppb, and particulate matter ≤1 /mL, almost free of ions, microorganisms, and organic matter.

2、Core process and equipment composition

Pretreatment system:

Multi-media filter: removal of suspended solids, colloids.

Activated carbon filter: adsorption of residual chlorine, organic matter.

Softener: removes calcium and magnesium ions (anti-scaling).

Reverse Osmosis (RO) systems:

97%-99% of the ions and organic matter are removed, and the conductivity of the produced water is less than 10 μS/cm.

Electrical deionization (EDI) systems:

Further purification to a resistivity ≥15 MΩ·cm was achieved by ion-exchange membrane and electric field.

Post-processing system:

Ultraviolet sterilization (UV) : Inactivates microorganisms.

Ultrafiltration (UF) : removal of pyrogen, nanoscale particles.

Polishing mixed bed: final purification, up to 18.2 MΩ·cm.

3、Key performance parameters

Parameter Typical values/Description

Water production resistivity ≥18.2 MΩ·cm (25℃)

TOC content ≤5 ppb

Particulate matter (≥0.1μm) ≤1 /mL

Water yield 0.5 m3/ H-100 m3/h (customized on demand)

Recovery rate 60%-85% (depending on raw water quality)

Operating pressure RO system: 1.0-1.5MPa; EDI system: 0.2-0.7MPa

4、Application field

Optical industry

Cleaning of various lenses.

Semiconductor Manufacturing:

Wafer cleaning, photoresist dilution, required resistivity ≥18.2 MΩ·cm, TOC≤1 ppb.

Biomedicine:

Water for injection (WFI) and biological agents are produced in accordance with GMP standards.

Laboratory:

Analytical instruments (HPLC, ICP-MS) use water to avoid background interference.

Pv and Lithium:

Solar silicon wafer cleaning, electrolyte preparation.

Product advantages

1、advanced equipment technology, exquisite workmanship

2、Long normal service life, high pass rate, to the technical level of imported equipment, more cost-effective.

3、our company has nearly 20 years of experience in technical and after-sales service team, from design and production to after-sales service to provide customers with professional solutions.

5、Selection and maintenance suggestions

Key points of selection:

Water quality requirements: The semiconductor industry needs 18.2 MΩ·cm, the pharmaceutical industry can relax to 15 MΩ·cm.

Water yield: +20% redundancy based on peak water consumption of production line.

Energy consumption: High efficiency RO membrane and low energy EDI module are preferred.

Maintenance:

Daily: Check the pressure, flow, and conductivity parameters and record running logs.

Monthly: Clean the RO membrane (chemical cleaning or reverse washing) and replace the pretreatment filter element.

Annual: EDI module ion exchange resin replacement, sensor calibration.

6、Common problems and solutions

Problem cause analysis solution

The particle settling stirring speed is insufficient or the time is too short to increase the rotational speed and prolong the stirring time

Temperature fluctuation large jacket medium uneven flow check pump valve, adjust flow

Seal leakage seal ring aging or improper installation Replace the seal ring, recalibrate the shaft

Motor overheating load is too large or poor heat dissipation reduce the speed, clean the heat dissipation fan

7、Technological development trends

Intelligent: The Internet of Things (IoT) monitors water quality in real time, and AI predicts membrane life.

Green energy saving: Develop low waste liquid discharge process, improve water recovery rate to more than 90%.

Integration: Ultra-pure water equipment is directly coupled to the production line to reduce the risk of water pollution.

For more models of products, please contact us. We will be happy to serve you!

在線留言