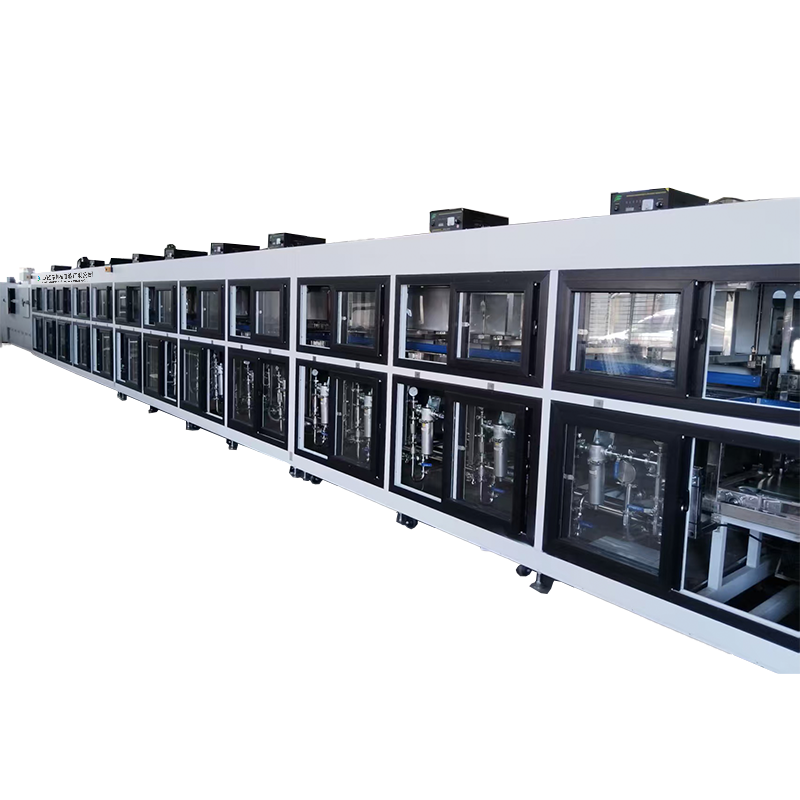

Fully Automatic Cleaning and Hardening Machine(Lines)

Product introduction

Cleaning & Hardening Machine: Core Functions and Technical Specifications

I. Core Functions & Process Flow

The cleaning and hardening machine is designed for optical lens cleaning and surface hardening treatments (e.g., anti-fog, anti-scratch coatings), integrating multi-stage processes to ensure lens cleanliness and durability.

Typical Process Flow:

Loading & Pre-Treatment: Automated feeding system transfers lenses into cleaning tanks.

Ultrasonic cleaning: high-frequency ultrasonic ( 40kHz / 68kHz) combined with environmental cleaning agents (deionized water, ethanol, etc.), remove surface oil, fingerprints and particle pollutants 1511.

Rinsing & Dehydration: Multi-stage pure water rinsing followed by slow-dip dehydration or hot-air drying to minimize watermarks.

Hardening Treatment: Chemical vapor deposition (CVD) or spray coating applies anti-fog/anti-scratch layers, enhancing surface hardness (≥9H).

Drying & Unloading: Final drying ensures coating curing; automated unloading boosts efficiency.

II. Technical Features & Key Parameters

Core Technologies:

Ultrasonic Cleaning System: Multi-tank design (cleaning, rinsing, pure water) with adjustable frequencies (28kHz–68kHz) for full-coverage cleaning.

Hard Coating Process: Anti-fog (e.g., IPA vapor bath) or chemical hardening (e.g., silane coating) to achieve ultra-hard surfaces.

Eco-Friendly Design: Closed-loop filtration for water-based cleaning agents, reducing chemical waste.

Key Parameters:

Parameter

Value/Range

Cleaning Speed

10–50 pcs/min (automation-dependent)

Temperature Control

Cleaning fluid: 25°C–60°C; Drying: 80°C–120°C

Cleanliness Standard

ISO 14644 Class ≤100

III. Application Scenarios

Optics Industry: Cleaning and hardening of eyeglass lenses, frames.

Consumer Electronics: Anti-scratch coating for mobile phone panels, automotive mirrors.

Medical & Research: Maintenance cleaning for laser optics, scientific instruments.

Product advantages

1、advanced equipment technology, exquisite workmanship

2、the normal service life of more than 15 years, the qualified rate of more than 95%, to reach the technical level of imported equipment, more cost-effective.

3、High cleanliness of equipment, special welding process for pipeline.

4、the manipulator can complete high-speed and accurate operation, replacing the uncertainty and inefficiency of manual operation, and realizing multiple tasks such as processing, assembly, handling and sorting.

5、our company has nearly 20 years of experience in technical and after-sales service team, from design and production to after-sales service to provide customers with professional solutions.

V. Industry Trends

Automation & Intelligence: AI vision inspection for contamination detection and parameter adjustment.

Green Technology: Solvent-free cleaning (e.g., supercritical CO?).

High-Precision Demand: Cleaning/hardening for micro-nano optical components (AR/VR lenses).

VI. Selection & Maintenance Guidelines

Selection Criteria:

Choose multi-tank/single-tank models based on lens size and production capacity.

Prioritize systems with HEPA filtration and precision temperature control.

Maintenance:

Replace filters (every 1–2 years) and cleaning agents regularly.

Calibrate ultrasonic generator power to prevent lens damage.

Production technology

Manual/automatic feeding → Washing with medicine water →Washing with RO water →Washing with DI water → Cutting water →Drying → Hardening → Precuring →Secondary hardening→Secondary curing →manually/ automatically feeding

Technical indicators

For more models of products, please contact us. We will be happy to serve you!

在線留言